|

Wondering Right Here! |

Evinrude 3 HP 1962

|

Meet the MasterTech! |

If your Mfgr. says: That motor's 7 years old!! Part is no longer available. We lose $$ on service! EPA made me do it! Part's at central warehouse, you'll get it next month. We don't make parts for those. We only do warranty work. Our techs only fix late models. No clue what's wrong! So we'll work time & material. Baloney!! Contact

|

|

TUNE UP YOUR MID SIZE JOHNSON/EVINRUDE OUTBOARD, SAVE $2,453.00 ON YOUR NEXT MID SIZE OUTBOARD MOTOR! Then you have come to the right place. We will go through the complete procedure to do a major tune up on a small motor, in this case a 1958 Evinrude 10HP I was lucky enough to find in a neighborhood yard sale. The seller said it didn't run but I could see from the images provided that it was in pretty good condition. Turned out to be almost unused! This particular model was built essentially unchanged from 1959 through 1963 and similar 7 1/2 thru 25 models manufactured up into the mid 80's.. You couldn't ask for better all round motors. Where do YOU get one? E-bay and other auction sites have motors up for sale all the time. Yard sales, flea markets, even your local dealer may be happy to sell you an older motor they don't think is worth repairing. Use good judgment, don't buy a motor that is worn out! Generally the nicer looking ones are in good shape. These are the steps to follow to get this little jewel into perfect condition. All these parts will cost you just a little over $175.00. The entire project should only take you a Sunday afternoon, and will reward you with a motor that runs better than new. HERE'S WHERE WE GET INTO RE-DOING THE WATER PUMP AND CARBURETOR

(click images for larger)

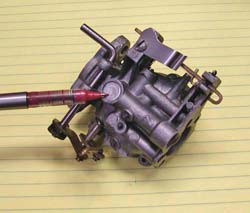

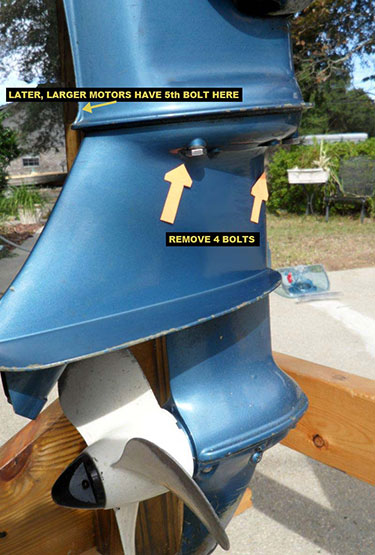

All old carburetors will need upgrading to alcohol resistant parts. To get started remove the fasteners and levers as shown above. Your motor may vary   Loosen screw and slide lever off the carburetor butterfly shaft  Nut on each side holds carburetor on Remove complete assembly. You will have to take off the high speed knob Here's a shot of the silencer (no, its' not a filter!) and carburetor off the motor These components are being replaced, except for the bug found in the carb bowl! Reassembling carburetor - be sure that you have all the varnish out. Most outboard manufacturers sell "engine cleaner" or "engine tuner" which is intended for decarbonizing but also works very well as a carburetor cleaner. Immerse, wash with water and blow dry. Not caustic, you can clean your hands with it. When the float needle and seat are correctly installed the float should be parallel to the body when inverted. Note the small spring on the needle goes over the float tang. Ok, lets take a look at the water pump. 1st thing to do is uncover the shift rod coupler

4 (or 5) bolts attach the gearcase to the midsection This has an acceptable impeller but the housing is worn excessively from running thru sand in our shallow bays and bayous. As you can see it is really easy to get to and service the water pump! |

|||||||||||

|

|||||||||||

Please review our Warranty, Returns & Refunds policies before you place an order. DISCLAIMER The information provided on these pages is correct to the best of my knowledge, however the MasterTech makes no warranty, express or implied, regarding the use of, results of, or liability created from, application of this data. This information is disseminated in good faith, however MasterTech assumes NO LIABILITY whatsoever in regard to this service. The information, software, products, and services published on this web site may include inaccuracies or typographical errors. Changes are periodically added to the information herein. Mastertech may make improvements to this site at any time. Parts ordered from this website may or may not be in dealer stock at the time of order. Thank you for reading.

| |||||||||||