|

Wondering Right Here! |

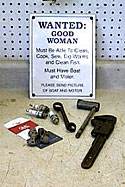

A Fun Old Porcelain Sign and Ancient Tools

|

Meet the MasterTech! |

If your Mfgr. says: That motor's 7 years old!!

Part is no longer available. We lose $$ on service! EPA made me do it! Part's at central warehouse, you'll get it next month. We don't make parts for those. We only do warranty work. Our techs only fix late models. No clue what's wrong! So we'll work time & material. Baloney!! Contact

|

|

If you want to see what can happen to that nice shiny outboard motor you just purchased for a small fortune, read on. These are just a few examples of what can happen in just a short time without proper care and feeding. Click on the pic to see the full size image. Use your browser's"Back" arrow or ALT/left arrow to return. These are just a few examples of what can happen to your equipment without proper care. A lot different than your car that cruises lazily down the freeway at 2500RPM. BE aware and diligently care for your outfit, it will return the favor with many years of trouble-free service. |

||

Please review our Warranty, Returns & Refunds policies before you place an order. DISCLAIMER The information provided on these pages is correct to the best of my knowledge, however the MasterTech makes no warranty, express or implied, regarding the use of, results of, or liability created from, application of this data. This information is disseminated in good faith, however MasterTech assumes NO LIABILITY whatsoever in regard to this service. The information, software, products, and services published on this web site may include inaccuracies or typographical errors. Changes are periodically added to the information herein. Mastertech may make improvements to this site at any time. Parts ordered from this website may or may not be in dealer stock at the time of order. Thank you for reading. Revised

|

||