|

Wondering Right Here! |

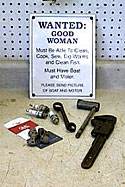

A Fun Old Porcelain Sign and Ancient Tools

|

Meet the MasterTech! |

If your Mfgr. says: That motor's 7 years old!!

Part is no longer available. We lose $$ on service! EPA made me do it! Part's at central warehouse, you'll get it next month. We don't make parts for those. We only do warranty work. Our techs only fix late models. No clue what's wrong! So we'll work time & material. Baloney!! Contact

|

|

Break In Your Motor Right!

Before starting your overhauled engine please do the following:

Break-in ProcedureStart your engine at home base using flush muffies to see that it actually does start and doesn't have any obvious problems i.e. - water leaks, etc... Once it is obvious the engine will start and run I suggest the engine be put in the lake and run for 20 minutes at high idle RPM (750 - 850) unloaded or out of gear. Check the plugs and carefully feel the engine to make sure it is not overheating. Restart the engine and then move it up to around 1500 RPM loaded in gear and vary the speed from idle until you have two hours on the engine. All the foregoing may be accomplished on the trailer. It is time consuming and tedious but it is the basis for long and happy engine life. If everything seems to be okay check the timing on #1 & #2 cylinders on a V-4 or V-6. Use the cylinder with the highest reading and set the timing 2-4 degrees less than the factory specs. If the spec is 24 degrees BTDC set the engine at 22 degrees. Leave the engine at this setting for the break-in period. If later you want more power the timing can be advanced to the factory spec but the engine will live longer if you leave the timing retarded. Don't guess. Use a timing light and set the timing UNDER LOAD, at FULL ADVANCE! Don't run it there other than to check the timing. At this point you can run the boat, cruise at 3000-3500 RPM, periodically giving it short runs up to full throttle. This should continue until there are ten hours on the engine, then your powerhead should be broken in. If you follow the outlined procedures you will get better service from your engine. Be sure that at maximum throttle the engine will turn up to 5500 RPM, the top operating RPM for most 2 strokes. If it doesn't the propeller should be changed until the engine runs at or slightly over the rated operating range with a light load. The wrong prop can cause the motor to lug, overheat or at the other extreme over rev and destroy all your good work. Be sure to check and retorque the cylinder head gaskets. Rebuilt Motor DO's and Don'tsYou must determine the reason the original powerhead failed. If the problem is not identified and corrected it is almost certain the newly rebuilt powerhead will fail. If a restricted (lean) carburetion problem caused the original powerhead to fail, the new one will also fail unless the problem is corrected. Guaranteed! The most common causes of engine failure are detonation, pre-ignition, and overheating or any combination thereof. The result of these problems is that the temperature in the combustion chamber gets too high. As soon as the temperature in the chamber gets higher than normal the engine begins to run poorly and the damage to the engine begins. Detonation is usually caused by the air/fuel mixture being lean and the erosion of the piston starts at the edge or outer diameter of the piston. If the erosion starts in the center of the piston it is probably an ignition problem. An engine running hot due to deteriorated water pump or cooling system blockage compounds the problem. The other common failure mode I see is scuffing and/or cold seizure which occurs mostly in new or rebuilt engines. When the engine is started, the piston heats up and expands quicker than the cylinder walls which are liquid cooled. When the engine is broken in and running at the correct operating temperature it runs with around .002 clearance. Normal human hair is about .003 inches. Once the rings are seated and a glaze forms on the cylinder walls this problem is not likely to occur. This makes the break in period very critical. The proper break in of a new or rebuilt powerhead will help insure that you get good value from your investment. |

||

Please review our Warranty, Returns & Refunds policies before you place an order. DISCLAIMER The information provided on these pages is correct to the best of my knowledge, however the MasterTech makes no warranty, express or implied, regarding the use of, results of, or liability created from, application of this data. This information is disseminated in good faith, however MasterTech assumes NO LIABILITY whatsoever in regard to this service. The information, software, products, and services published on this web site may include inaccuracies or typographical errors. Changes are periodically added to the information herein. Mastertech may make improvements to this site at any time. Parts ordered from this website may or may not be in dealer stock at the time of order. Thank you for reading. Revised

|

||