|

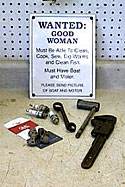

Wondering Right Here! |

|

Meet the MasterTech! |

If your Mfgr. says: That motor's 7 years old!!

Part is no longer available. We lose $$ on service! EPA made me do it! Part's at central warehouse, you'll get it next month. We don't make parts for those. We only do warranty work. Our techs only fix late models. No clue what's wrong! So we'll work time & material.

Baloney!! Contact

|

|

Outboard cooling systems in general are quite reliable. As the size of the motor increases however the complexity also increases and you must check all the components for proper functionality. To and including temperature sensors, thermostat(s), pressure relief/bypass valves, overboard hoses and fittings. Cooling system and waterpump ills can be alleviated by replacing the pump every so often. Impellers take a set when unused and can shed vanes fast when you operate the outboard after an extended period of storage. I advise that ANY motor which has been idle for more than 1 year have a VISUAL check of the pump. It's real easy to install a new impeller and avoid extensive engine damage caused by an overheat.

Run your motor without water, and the impeller

and housings on a modern outboard will be ground into scrap in

30 seconds or less! Should you find that the pump has self-destructed due to lack of water, be VERY CAREFUL to be certain that fragments of the impeller have not passed into water tube and block and restricted passages. If you suspect that you have not recovered all of this material, better safe than sorry and remove ALL the covers and clean it out. IF your motor has suffered a cooling system failure, there are several factors to consider depending on the severity. You MUST replace the head gasket as overheating will turn it into carbon and its sealing properties will be destroyed. Check the exhaust cover gaskets as well. Motors equipped with thermostats, will generally require replacement of the stat as well as the pressure relief bypass valve, a plastic part that will likely be melted. A severe overheating could have damaged the pistons and rings. If removal of the head shows any parallel vertical lines in the cylinders, or worse yet, aluminum transfer to the walls you should remove the transfer covers and the exhaust plate to check the pistons for scuffing. Many times transferred aluminum can be removed from the cylinder walls with Muriatic acid. Observe common sense precautions when using this strong acid! CAREFULLY, using a cotton swab, apply only to the affected area until it stops fizzing, the aluminum deposits will be eaten away. You must thoroughly neutralize the acid with baking soda after cleaning off the aluminum! A light scuffing up to remove embedded carbon and restore some crosshatch with some oiled 320 grit wet-or-dry sandpaper will heal up a slightly scuffed cylinder. To help the motor heal itself from the distortions caused by an overheat, I recommend you run it on a 24:1 oil mixture for several hours as well as limiting the speed to 1/2 throttle or less. When you finish initial testing on an overheated engine, be sure to retorque the fasteners on all covers removed to check it over as well as retorquing the head gasket. IF you wish to service or repair your own cooling system, I HIGHLY RECOMMEND you obtain an OEM model-specific service manual to help you. We have most available Right Here at Mastertech. |

|||||||||||||||||

|

|||||||||||||||||

|

Please review our Warranty, Returns & Refunds policies before you place an order. DISCLAIMER The information provided on these pages is correct to the best of my knowledge, however the MasterTech makes no warranty, express or implied, regarding the use of, results of, or liability created from, application of this data. This information is disseminated in good faith, however MasterTech assumes NO LIABILITY whatsoever in regard to this service. The information, software, products, and services published on this web site may include inaccuracies or typographical errors. Changes are periodically added to the information herein. Mastertech may make improvements to this site at any time. Parts ordered from this website may or may not be in dealer stock at the time of order. Thank you for reading. Revised: November 19 2019

| |||||||||||||||||