|

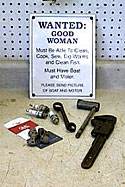

Wondering Right Here! |

|

Meet the MasterTech! |

If your Mfgr. says: That motor's 7 years old!!

Part is no longer available. We lose $$ on service! EPA made me do it! Part's at central warehouse, you'll get it next month. We don't make parts for those. We only do warranty work. Our techs only fix late models. No clue what's wrong! So we'll work time & material. Baloney!! Contact

|

|

The subject of the outboard ignition system could fill a phone book! I will only try to give a general procedure to follow here, the variety of systems used is boggling to the mind. Keeps engineers busy I suppose. The simplest system is the flywheel magneto. First thing to have handy to service this is the correct type of flywheel puller. All outboard flywheels are pulled from the center, under no circumstances attempt to remove a flywheel by use of a gear puller that hooks under the outside edge. You WILL ruin it! Almost all ignition systems incorporate some sort of a stop switch. The FIRST test of any system is to simply disconnect this circuit AT THE SOURCE to determine if there is a simple short in the wiring or switches. On most new CDI systems this wire has been standardized as a black wire with a yellow stripe. While we are on the subject of grounds, be sure all the coil, CDI pack and mounting bracket ground leads are clean and have continuity. If there's no ground, the system won't work. On a magneto energized CDI system, take a visual look at the stator up under the flywheel. Is it leaking honeylike liquid potting compound onto the top of the block? Drips hanging off the coils? Cracks/burned spots? Even if the electrical values are on spec, a stator showing any of these symptoms is NO GOOD and must be replaced. This applies to any other potted component as well. There is a definite relationship between the charging

circuit and the ignition on all CD systems. It is IMPERATIVE that

all battery connections be clean and tight. I recommend a marine

type battery with threaded posts to accept your battery cables.

Toss the wing nuts and use stainless steel elastic lock nuts. Mount

excessive accessory leads on a separate terminal; many newer marine

batteries have 2 on each side. Test the rectifier/regulator to be

sure the system is charging.

IF you wish to service or repair your own

ignition system, I HIGHLY RECOMMEND you obtain a

service manual to help you. Meanwhile, you can check out this Troubleshooting Precedures guide from CDI Electronics for some test procedures for various ignition systems.

|

|||||||||||||||||

We pay the freight out in USA on all orders over $100.00. Orders less than this amount will have a shipping and handling charge of $8.75 added. Some bulky and heavy items will incur additional charges. You will be notified beforehand if this is the case. Remember, all orders receive free technical support from the MasterTech! |

|||||||||||||||||

Please review our Warranty, Returns & Refunds policies before you place an order. DISCLAIMER The information provided on these pages is correct to the best of my knowledge, however the MasterTech makes no warranty, express or implied, regarding the use of, results of, or liability created from, application of this data. This information is disseminated in good faith, however MasterTech assumes NO LIABILITY whatsoever in regard to this service. The information, software, products, and services published on this web site may include inaccuracies or typographical errors. Changes are periodically added to the information herein. Mastertech may make improvements to this site at any time. Parts ordered from this website may or may not be in dealer stock at the time of order. Thank you for reading.

| |||||||||||||||||